Nonresidential Pipe Sizing and Leak Testing for Compressed Air Systems

Measure Description

This measure includes a series of changes to the compressed air system requirements in Title 24, Part 6 based on energy calculations, measure costs, market characteristics, and stakeholder input. Although the supply side of compressed air systems have been covered since the 2013 Title 24, Part 6 code cycle, the proposal expands coverage to include demand side measures. The proposed changes are mandatory and would impact any facility that has permanent compressed air system triggered by the requirements. Most of the covered situations would be in industrial and manufacturing buildings.

Pipe Sizing of Compressed Air Distribution Systems

The pipe sizing measure would require selection of pipe diameters in line with recommended best practices to mitigate frictional pressure losses in the distribution network. This requirement would apply to any new construction piping installation or added piping over 50 adjoining feet in length. The measure would reduce unnecessarily high compressor discharge pressures. Compressor discharge pressures are often elevated to overcome excessive distribution piping pressure drops, which can be avoided through proper pipe sizing specifications. Compliance would be achieved through a plans design review and potentially a visual inspection after installation to confirm that diameters are equal to plan specifications.

Monitoring for Leak and Efficiency Maintenance

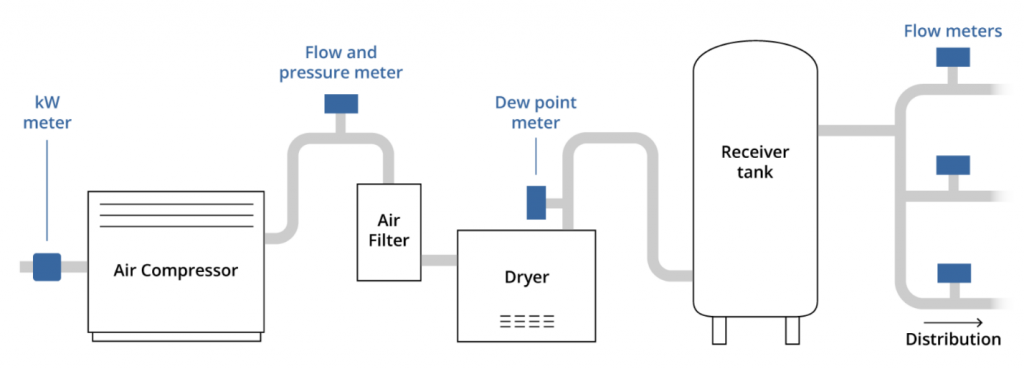

The monitoring measure would require the installation of meters which would facilitate continuous monitoring of energy, load, and efficiency of any new compressed air system with capacities greater than or equal to 100 horsepower (hp).

Additions or replacements of compressors to existing systems would also trigger this requirement if the 100 hp threshold is met. The measure would require that system pressure and airflow be monitored as well as power of each individual compressor. The monitoring system shall include power (kW), pressure (psig), load (cfm), and specific efficiency (kW/100 cfm), at a minimum. This would ensure that load growth due to leaks is identified, providing direct economic feedback when leakage rates are excessive and necessitate detection and repair. This type of monitoring can directly address the primary barriers to proper compressed air system management and energy efficiency maintenance. When combined with isolation valves, one could potentially use this monitoring system to identify which portions of the compressed air system is leaking. Even if existing code requirements are satisfied, specific efficiency monitoring could help flag issues – those caused by control system parameters or otherwise – that can cause a system to operate inefficiently. Compliance certification would be achieved by an acceptance test conducted by the installing technician of installed meters and monitoring output.

Leak Testing of Compressed Air Piping

The leak testing requirement applies to new construction of compressed air systems and to additions and alterations of over 50 adjoining feet in length. Any adjoining lengths greater than 50 feet would be tested for leaks according to a pressure test and any shorter lengths can be tested using a leak-detection fluid. Both of these methods are already codified for natural gas systems in the California Plumbing Code. This would ensure that leaks are not present at installation, codify best practices, and mitigate leaks in inaccessible header and distribution piping before plants or new end uses are operational. Compliance would be confirmed by the submission of an installation certificate by the installing contractor and confirmed by pressure gauge observation by the building inspector, similar to current natural gas piping verification.

Clean-up of Existing Language

Several clean-up measures that do not impact stringency are recommended. Removal of the term “online” from the existing language is necessary to streamline compliance, reduce confusion, and facilitate downstream programs. The use of “online” to designate which compressors are back-up is not an industry standard term, nor is it evident in any given plant whether a compressor should be considered “online.” This change would help mitigate confusion generated by the existing language as reported by stakeholders.

The existing language exempts alterations to any system that has a centrifugal compressor for all existing requirements. Although the 2013 CASE Report found that the existing measures were cost-effective for systems with centrifugal compressors, this exception was inserted during rulemaking in response to stakeholder feedback regarding limited compliance options and feasibility concerns. Advanced controls for centrifugal compressors were less feasible at the time. However, controls have advanced since then and products for the various situations that include centrifugal compressors are readily available. The proposed clean-up suggests removing the exception to the existing controls requirement which was originally found to be cost-effective for the centrifugal system prototype in the 2013 CASE Report. Additionally, the exception must be moved to ensure that the proposed new requirements apply to systems with centrifugal compressors.

Beyond these two clean-up changes, there are other, small changes to help simplify and clarify the language without any effect on intent or coverage.

None of the proposed changes require any modification to compliance software. Compliance software does not currently include compressed air, and the Statewide CASE Team does not recommend that it should.

Relevant Documents

Measure proposals, supporting documents, and other outside references will be made public as they become available.

- CASE Study Results Report – Nonresidential Pipe Sizing and Leak Testing for Compressed Air Systems

- Final CASE Report – Nonresidential Pipe Sizing and Leak Testing for Compressed Air Systems

- Draft CASE Report – Nonresidential Pipe Sizing and Leak Testing for Compressed Air Systems

- Covered Processes Part 2 Submeasure Summary

- Presentation – Nov 7th – Covered Processes Part 2

- Notes – Nov 7th – Covered Processes Part 2

Provide Feedback

View the Energy Commission’s proposed code language and submit feedback by visiting this link.

This measure page will be updated as the 2022 code cycle progresses. For questions or suggestions, email

[email protected]. Include the measure name in the subject line..

-

Use the form above to provide feedback on this measure.

Give Us Your Feedback

The Statewide CASE Team values input from all stakeholders engaged in the Title 24, Part 6 code change process. We encourage the open exchange of code change comments and concerns.